Process Safety Engineering

Protecting your most important assets:

your people

your people

Whether you are carrying out a safety review, implementing safety audits or ensuring compliance with standards or regulations, we have the up-to-date resources and skills to complete the task. And if you require help with problem solving or incident investigation, you can rely on impartial advice and support from our experienced team whenever you need it.

A large number of businesses use dangerous substances within their processes and have a duty to demonstrate that they have fully identified and managed the associated risks. If this applies to you, does your business have an effective basis of safety in place to control risk?

The development of a Process Safety management system is vitally important in minimising the risk of equipment failure, fire and explosion, and loss of containment incidents, all of which have the potential to seriously harm human health and/or the environment. Such incidents can also result in major breaches of legislative compliance, with the potential for significant reputational and financial losses.

Regardless of your business size or specialty, our experienced and approachable team will assist you in identifying and better understanding your site-specific hazards, and evaluating risk, as well as advising on legal responsibilities and best practice control measures to ensure your operational risks are minimised.

COMAH Regulations Compliance Support

With a detailed knowledge of COMAH (Control of Major Accident Hazards) Regulations, our process safety team is experienced in the provision of a variety of COMAH-related consultancy services to assist our clients in strengthening their compliance, minimising their risk, and aligning with industry best practice.

- Hazardous substance inventory calculation and COMAH status check.

- Hazardous Substance Consent application support.

- Hazard identification and analysis studies(e.g. Major Accident Hazard Identification/HAZID/HAZOP).

- Functional Safety and Layer of Protection Analysis (LOPA).

- Major accident consequence modelling.

- Hazardous area classification and risk assessment.

- COMAH Safety Report preparation assistance and ALARP evaluations.

- Occupied Building Risk Assessment (OBRA).

- Quantitative Risk Assessments and Analysis (QRA).

- Environmental risk tolerability assessments (CDOIF).

- Occupational health and safety services.

- Human factors analysis.

- Safety and environmental training

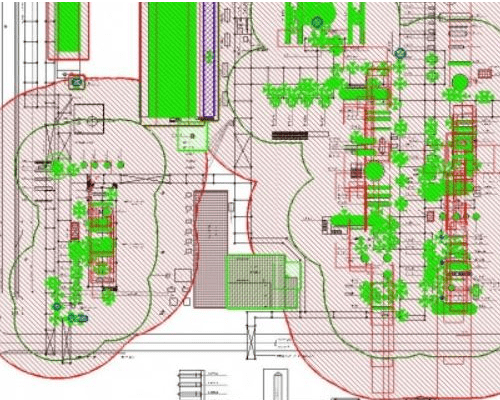

Hazardous Area Classification

Do you store or handle dangerous substances under DSEAR? These can include flammable gases, vapours or liquids, combustible dusts, oxidising materials, compressed gases, or materials corrosive to metal. Processing or storing dangerous substances poses a potential threat of fire, explosion or other energy-releasing events.

The Dangerous Substance and Explosive Atmospheres Regulations 2002 (DSEAR) specify the minimum requirements for protecting people from these risks.

- Prepare a suitable and sufficient risk assessment.

- Eliminate and reduce the risk from dangerous substances.

- Complete a formal Hazardous Area Classification (HAC).

- Manage ignition sources within hazardous areas.

- Establish provision to deal with accidents, incidents and emergencies.

- Provide information, instruction and training to all relevant personnel.

- Ensure dangerous substances can be identified on site.

- Even without a serious incident that results in damage, injury or loss of life, non-compliance can have serious consequences, with those found in breach of DSEAR subject to heavy fines or even jail time.

Exponent DSEAR Services

- Identification of dangerous substances that may apply under DSEAR.

- Risk Assessments to assess the likelihood and consequences of releases associated with the storage and handling of dangerous substances.

- Preparation of a prioritised action plan to mitigate the risk and develop a Basis of Safety.

- Preparation of HAC Schedules and Drawing Mark-Ups to indicate extent of hazardous zones.

- Advice on selection of equipment within ATEX zones, and risk of ignition from mechanical sources such as mixers via Mechanical Equipment Ignition Risk Assessment (MEIRA).

- Design of engineering solutions.

- Advice on area signage and labelling requirements.

- Site-specific DSEAR awareness training.

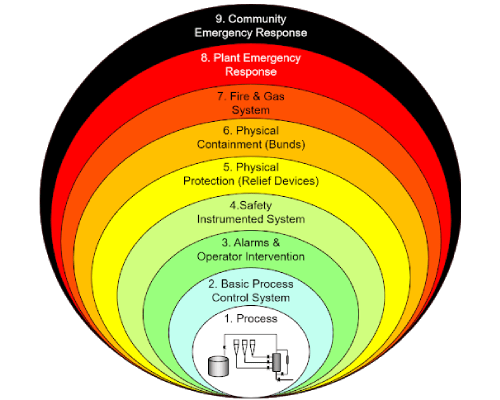

Functional Safety

Exponent can provide both qualitative and quantitative Layer of Protection Analysis (LOPA) studies to enable detailed assessment of specific process risks, and hence determine business-specific requirements for safety instrumented functions and associated Safety Integrity Level (SIL) target specification.

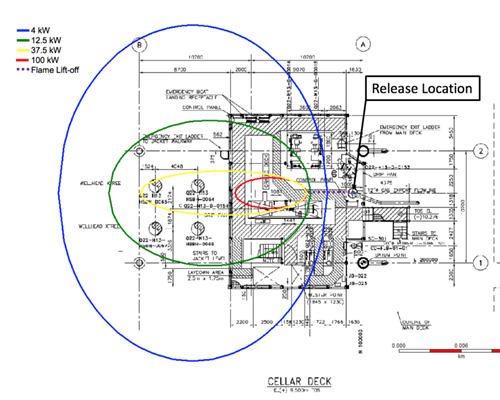

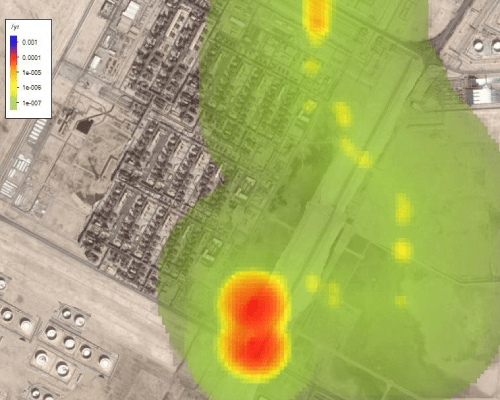

Consequence Modelling

Exponent can offer a range of modelling solutions to assess potential consequences of process releases, including, Pool Fires, Jet Fires, Flash Fires, Vapour Cloud Explosion (VCE), Smoke and Toxic Gas Dispersion. Exponent is experienced in using either empirical calculations or the latest industry software, such as PHAST (DNV), ADMS (CERC), etc., depending on the nature of the scenario.

- COMAH Safety Reports,

- Offsite impact analysis,

- Emergency Response Plans (ERP),

- Site layout and design – Occupied Building Risk Assessment (OBRA)

Hazard and Operability Studies (HAZOP)

The Hazard and Operability Study (HAZOP) technique is the most widely-used and established approach for identifying the hazards, risks and potential consequences associated with chemical and industrial processes. Exponent can provide a fully qualified Team Leader and Scribe to lead your HAZOP study, as well as independent Process Engineering support within the study group.

Exponent can also provide hazard identification (HAZID) and environmental hazard identification (ENVID).

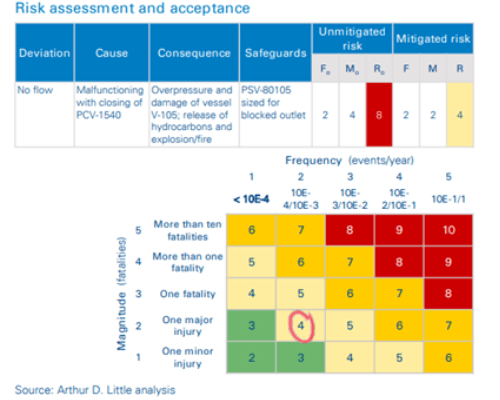

Risk Analysis Studies

Exponent can provide probabilistic and non-probabilistic risk analysis to determine the potential for harm to personnel and public, assets and environment. Exponent will use techniques such as Fire and Explosion Risk Analysis (FERA) and Quantitative Risk Assessment (QRA) to determine the potential for immediate injury or fatality from incidents, injuries during any evacuation and escalation to other areas of the site. Exponent will develop studies such as Smoke and Gas Ingress Analysis (SGIA) and Emergency System Survivability Analysis (ESSA) and to determine the vulnerability of non-process buildings or auxiliary systems.

By carrying out a risk reduction workshop, Exponent will work together with you to demonstrate risk is As Low As Reasonably Practicable (ALARP) and develop cost-effective solutions to minimise risk.

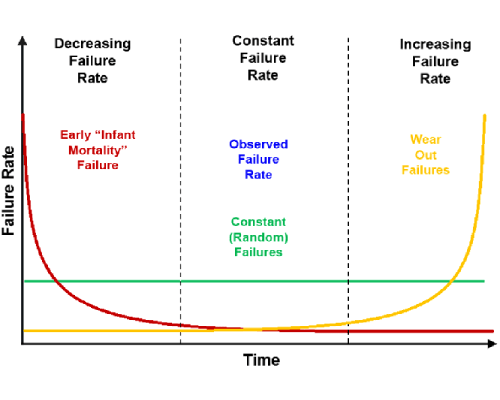

Reliability Engineering

Exponent can provide services to analyse and optimise the ability of complex systems to perform throughout a project lifecycle. Techniques such as Failure Mode Effect and Criticality Analysis (FMECA) can determine the how individual equipment and systems can fail, and the impact on the overall system.

Exponent can provide Reliability Availability and Maintainability (RAM) modelling, predicting how the system will perform, key contributors to system downtime, and how up-time can be optimised via changes to equipment configuration, maintenance and sparing philosophy.